PVC windows – Five strong arguments for PVC windows as a sustainable construction product

Modern PVC windows carrying the RAL quality mark offer a great many advantages: they consist of sustainably sourced raw materials, are extremely long-lasting and help cut energy costs. They also contribute to healthy living and environmental compatibility. Once the windows have reached the end of their useful life, they can be recycled.

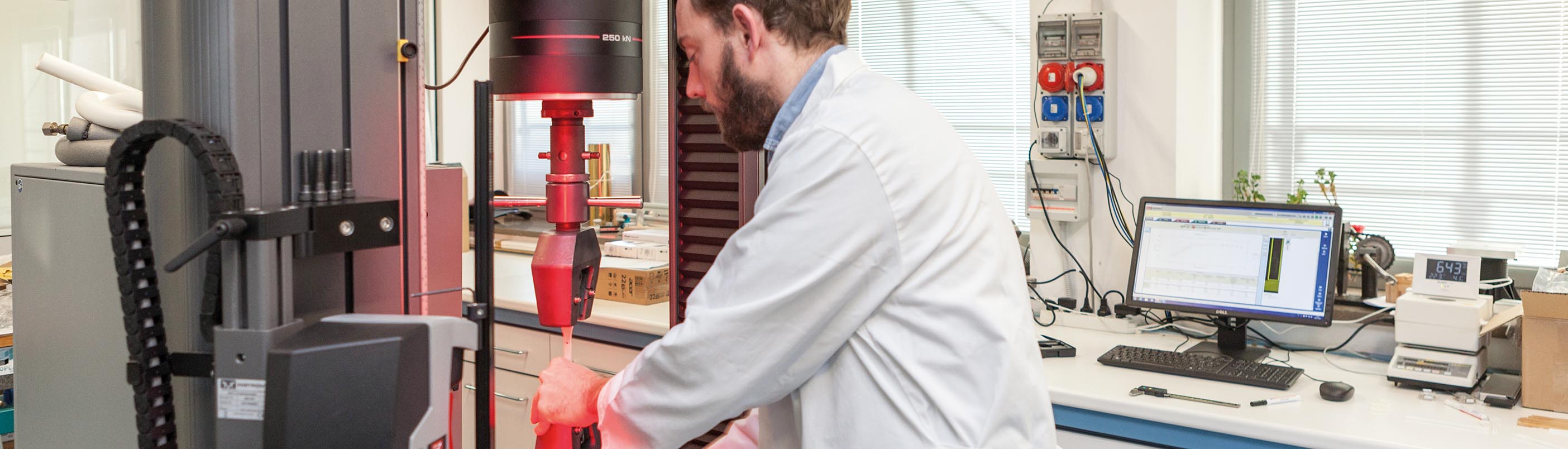

Long life / suitability for continued use

PVC windows carrying the RAL quality mark must meet particular mechanical and material requirements that are monitored regularly by independent test institutes. These requirements are usually more stringent than those of product standards. The same applies for the profile system, the insulating glass and fittings components, and assembly. This ensures long life and suitability for continued use. RAL quality-assured PVC windows are in use for 40 years or longer.

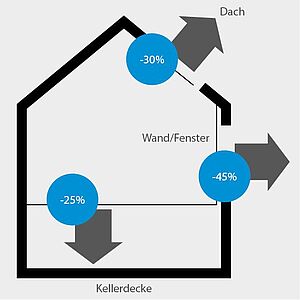

Reduced energy consumption

New windows enable you to reduce your annual energy consumption by more than 40%. This can be achieved if, for instance, you replace windows that are 15 to 20 years old with new, triple-glazed PVC systems. You can identify good thermal insulation by what is known as the UW value. For double-glazed windows it averages out at 1.3 W/(m2K), for triple-glazed windows at less than 1.0 W/(m2K). PVC windows below 0.80 W/(m2K) are possible with special equipment meet the requirements of the passive house standard. Further information can be obtained from our system providers.

By the way, the Kreditanstalt für Wiederaufbau (KfW) and the German federal states offer a range of subsidy options for the installation of energy-efficient windows. “Programm 430” (individual energy measures), for instance, refunds 10% of the eligible costs up to 5,000 euros for each housing unit. For further information, go to www.kfw.de.

Healthy living

“Healthy living” first and foremost means avoiding harmful emissions indoors. The Deutsche Institut für Bautechnik (DIBt) requires use of the evaluation scheme produced by the Ausschuss zur gesundheitlichen Bewertung von Bauprodukten (AgBB), the committee assessing the health standards of construction products. Quality-assured PVC windows meet these requirements. More information can be found in our Environmental Product Declarations for PVC windows, which can be obtained from the Institut Bauen und Umwelt (IBU): www.ibu-epd.com.

Sustainability and environmental compatibility

Environmental compatibility is ensured along the entire lifecycle of quality-assured windows, from manufacture through to disposal. VinylPlus, the sustainability programme of the European PVC industry, goes one step further: programme partners undertake e.g. to use raw materials from sustainable production and to promote PVC recycling. For 2020, 800,000 t are planned and for 2025, 900,000 t PVC recyclate. Furthermore, they must develop and implement energy-saving plans. Window profile manufacturers of the Gütegemeinschaft have accepted this challenge and acquired the VinylPlus Product Label as part of an independent audit. For further information, go to www.vinylplus.eu.

Valuable raw materials supplier

A window frame can be recycled up to seven times without any loss of quality for the new window profile made from it, as results from long-term analyses carried out by the RAL Gütegemeinschaft demonstrate. It is good for the environment that the manufacturing process does not rely solely on virgin material. This both protects valuable raw materials such as crude oil and reduces the consumption of energy required in raw material and window profile production. Emissions of greenhouse gases and other pollutants are thereby cut. Each tonne of PVC recyclate that is used for new profiles saves almost 2 t of CO2 compared with primary PVC.

As you can see, these are five strong arguments for PVC windows as a sustainable construction product.